Frequently Asked Questions

What is RF and EMI shielding?

RF (Radio Frequency) and EMI (Electromagnetic Interference) shielding are protective metal cages designed to block or reduce electromagnetic interference that can affect electronic devices. By using conductive or magnetic materials, these shielding solutions prevent disruptions to sensitive components, ensuring optimal device performance and compliance with industry regulations.

Discover how our EMI and RF shielding solutions can enhance your products' reliability.

Why is RF and EMI shielding important?

RF and EMI shielding are essential to protect electronic devices from interference that can lead to malfunctions, data loss, and degraded performance. This is especially critical in wireless communication applications where reliable electric operation is vital.

Explore our range of high-performance EMI and RF shielding solutions to keep your devices running smoothly.

How does an RF and EMI shield work?

An RF and EMI shield works by creating a barrier that absorbs or reflects electromagnetic waves. Typically made from conductive materials like tin-plated steel, copper, or aluminum, this barrier maintains signal integrity and prevents devices from emitting or receiving harmful interference.

Learn more about how our shielding solutions can safeguard your electronic components.

What materials are used for RF and EMI shielding?

Common materials used in EMI and RF shielding include tin-plated steel (CRS), nickel-silver, copper, brass, aluminum, and more.

Check out our stock of raw material alloys and learn about proper RF shield storage and handling. Additional materials are available upon request.

Which industries require RF and EMI shielding solutions?

Industries that heavily rely on EMI and RF shielding include:

> Aerospace & Defense: Protecting avionics and communication systems from interference.

> Medical Devices: Ensuring the safe operation of sensitive diagnostic equipment.

> Telecommunications: Maintaining signal clarity in wireless and wired communication devices.

> Automotive: Safeguarding electronic control units (ECUs) and infotainment systems.

Find out how our shielding solutions support various industries and markets.

How do I choose the right EMI/RF shielding solution for my application?

Choosing the right shielding solution depends on factors like operating frequency, environmental conditions, regulatory compliance, and specific device design. At Masach, we specialize in the mechanical aspects of our shields, offering detailed specifications filters on our website under Drawn-Seamless EMI/RFI Shields. Customers can easily find the right shield based on dimensions, material, mounting type, and more.

Our 3D models and footprint files are available for instant download to support the initial stages of PCB design. Factors such as temperature ranges, shielding effectiveness, and soldering profiles should be determined by your assembly or lab team according to your specific application needs.

Need assistance? Our team of experts is here to help you find the perfect EMI/RF shielding solution.

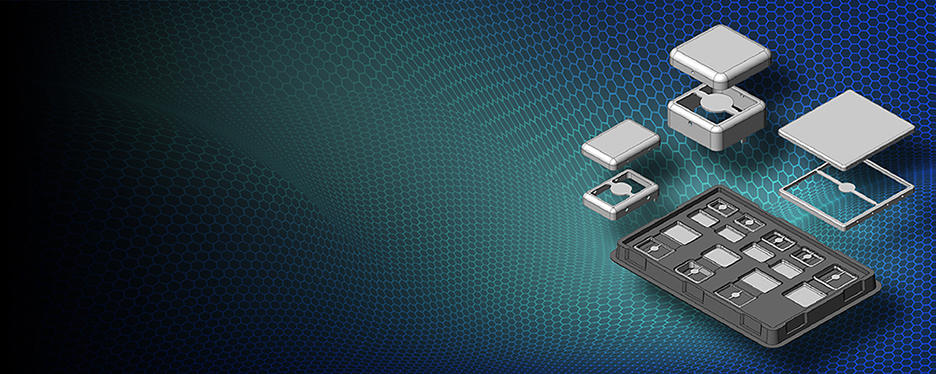

What are Drawn-Seamless EMI & RF shields?

Drawn-seamless EMI/RFI shields provide superior, long-term performance, particularly at high frequencies, due to their hermetically sealed design. Masach™ Drawn-seamless EMI/RFI shields are engineered for optimal shielding effectiveness, leveraging a unique hermetic fabrication process, making them the preferred choice for demanding high-frequency applications.

Features & Benefits:

> Seamless Protective Cage: Ensures higher shielding effectiveness.

> Optimal Planarity: Facilitates higher yields during reflow soldering.

> Solid Construction: Resists dents and warps, providing robust protection.

> Two-piece Shield Design: Enables efficient component repair without removing the shield, minimizing downtime and potential damage.

Explore our selection of Drawn-Seamless EMI/RFI shields.

Why use Masach™ Standard Drawn-Seamless EMI & RF shields?

Masach provides the electronics industry’s most extensive range of EMI and RF shields, featuring a comprehensive library of hundreds of sizes and configurations. This ensures unparalleled flexibility during the design phase. Our standard EMI/RFI shields are designed to significantly reduce development costs and accelerate time-to-market by eliminating the need for costly custom prototypes.

Crafted from high-quality materials such as tin-plated steel and nickel-silver alloys, Masach’s drawn-seamless shields deliver exceptional mechanical formability, environmental compliance, and cost-effectiveness, making them ideal for board-level shielding applications.

To simplify your design process, engineers can access detailed mechanical specifications, including downloadable PDF datasheets and 3D CAD files, directly from our product pages.

Download datasheets and CAD files to start your design today.

When is a two-piece shield with a removable cover necessary?

Two-piece shields provide essential access to shielded areas of the PCB, simplifying maintenance and repairs. They are crucial when components within the shielded area require access without removing the entire shield.

Discover how Masach's two-piece RF shields streamline maintenance and repair operations.

When is a one-piece shield the optimal choice?

A one-piece shield is the optimal choice in scenarios where internal access to components is unnecessary after assembly, and where durability, cost efficiency, and superior EMI/RF shielding effectiveness are prioritized. These shields are particularly advantageous for surface-mount technology (SMT) assembly due to their simplicity, robustness, and ability to provide consistent shielding performance.

However, careful consideration must be given to soldering specifications, such as proper heat profiles, to ensure effective assembly without causing heat damage to internal components. In cases where thermal management is a concern, features like shield ventilation or through-hole ventilation in the PCB may be necessary. Collaboration with the assembly team or lab is essential to define these requirements and ensure optimal performance.

Find the right one-piece shield for your next project.

How do I select the appropriate EMI/RF shielding solution for my application?

Choosing the right shielding solution depends on several critical factors, including operating frequency, environmental conditions, regulatory compliance, and specific device design. At Masach, we focus on the mechanical aspects of our shields, providing detailed specifications and filters on our website under “Drawn-Seamless EMI/RFI Shields.” Engineers can efficiently locate the ideal shield based on dimensions, material, mounting type, and other relevant criteria.

3D models and footprint files are readily available for download to support the initial stages of PCB design. Specific requirements such as temperature ranges, shielding effectiveness, and soldering profiles should be determined by your assembly or lab team in accordance with your unique application needs.

Need expert guidance? Contact our team for personalized EMI/RF shielding recommendations.

What raw material are available?

Masach's stock materials include a variety of brass and steel alloys, such as Tin-plated Steel (CRS) and Nickel-Silver. These materials are the most cost-effective and widely used solutions for EMI/RFI shielding. Additionally, other conductive materials can be sourced upon request to meet specific client requirements.

What is the difference between Tin-plated Steel (CRS) and Nickel-Silver items?

Tin-plated Steel (CRS) shields are commonly used in applications where general environmental resistance is sufficient. In contrast, Nickel-Silver shields are preferred for more demanding environments, particularly in sensitive industries such as Medical, Aerospace, Automotive and Marine among others, where resistance to rust and harsh conditions is critical.

For more details, please view our Online Library and filter by “Tin-plated Steel" or "Nickel-Silver” to explore our high-performance RF shield options. Please also refer to our Standard Raw Material Alloys / RF Shields Storage & Handling.

Can I receive the shields pre-packed for automatic assembly?

Masach™ Standard Drawn-Seamless EMI/RFI shields are SMT-compatible and are typically supplied pre-packed in SMD trays as standard. For customers who require tape-and-reel (T&R) packaging, this option is available upon request. Please note that T&R packaging is subject to the dimensions of the item. Items packaged in T&R will be assigned a new part number specific to the tape-and-reel packaging.

Where can I order small quantities of Drawn-Seamless EMI & RF shields for prototyping?

As part of our global operations, we have established online stocking distribution channels to offer our partners and customers the ability to order small to medium quantities at competitive prices with fast lead times.

For more information, please visit the "Find a Distributor" section on our Contact Us webpage.

Does Masach offer custom design EMI and RF shields?

Yes, Masach provides comprehensive engineering and design services for custom EMI and RF shields. With extensive experience in designing RF shields for major telecom companies and manufacturers, we are well-equipped to handle your custom shield engineering needs.

Visit our Custom EMI/RFI Shields webpage to learn more.

What options do I have for custom shield design?

Masach can design a custom shield for you from scratch or collaborate with you on your design. However, we recommend exploring our extensive library of Drawn-Seamless EMI/RFI Shields first. Utilizing our standard shields can save on custom design costs and significantly reduce delivery times. PDF datasheets and 3D-CAD files are available for download on our product pages, and all products are globally available in-stock.

What information is needed for a new custom shield design?

For new custom shield designs, please provide the following information for our evaluation:

> 3D model of the shield

> Quantity required for prototyping

> Estimated production volume

> Project time frame

Is there a minimum ratio between wall thickness of the shields and the width of the solder pad on a PCB?

For optimal soldering results, we recommend maintaining a minimum ratio of 0.3mm between the wall thickness of the shields and the width of the solder pad on the PCB. This means 0.15mm on each side of the shield. Additionally, for drawn-seamless EMI and RF shields, ensure that corner radiuses are considered as per the item's specifications.

Contact our support team for specific requirements.

Does your shields undergo cleaning during production?

Cleaning is a critical step to ensure the shields are free from contaminants, oils, or residues, which guarantees they meet quality standards and are ready for use. All Masach's shields undergo a comprehensive cleaning process using our advanced degreasing system, ensuring they meet the highest standards of cleanliness before being packaged.

Do you offer custom modifications to your standard Drawn-Seamless EMI/RF shields?

Yes, Masach offers optional modifications to our standard RF shields to meet your specific requirements. These modifications include:

> Ventilation Holes: To address overheating issues, especially in high-powered devices generating heat inside the shielded enclosure. Explore our Online Library and filter by “Vented” to view our perforated RF covers.

> Mouse-Hole for PCB Trace Routing: We can add a "mouse-hole" to our RF frames, allowing PCB traces to be routed out of the shielded region on the top layer of the PCB. For more details, check out our case study: Adding Mouse Holes to Standard RF Shields.

> Height Reduction: If the standard height of our shields does not meet your specifications, we offer the option to reduce the height of certain standard RF shields. Please note that this modification requires a case-by-case review by our engineering team to ensure feasibility.

How do I find Masach's standard shield designs?

Our standard Drawn-Seamless EMI/RFI Shields are available in our Online Library. PDF datasheets and 3D-CAD files can be downloaded directly from the product pages on our website. All products are in-stock through our online global distribution network and ready for global delivery.

Is it more efficient to modify an existing standard shield than to design a new one?

Absolutely! Modifying an existing standard shield is often a cost-effective and time-efficient solution. We offer modifications such as ventilation holes, mouse-holes for PCB trace routing, and height reduction. Contact us to discuss your specific needs, and our team will guide you through the process.

Contact our support team for further assistance.

Does Masach's EMI & RF shields comply with industry standards?

Masach Tech's EMI and RF shielding solutions are fully compliant with global industry standards, including:

> ISO 9001:2015 Quality Management Systems

> AS9100D Aerospace Management Systems (AMS)

> ISO 14001:2015 Environmental Management Systems (EMS)

Are your products RoHS or REACH compliant?

Yes, we prioritize environmental and safety standards. All applicable products are fully compliant with RoHS and REACH regulations. View our online EU RoHS & Reach Declaration.